24 OURS SHIPPING!

Processing Stones

Bush-hammering

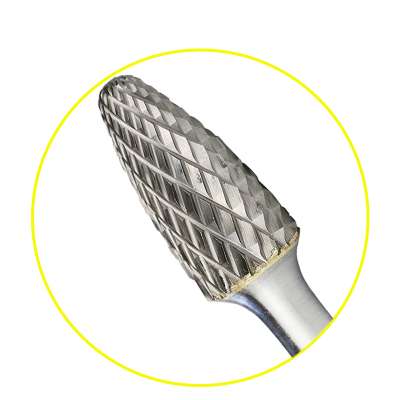

Bush-hammering is a processing technique used to give stone, marble, and granite slabs a rough and corrugated finish, known as Bush-Hammered. This type of finish is particularly suitable for outdoor pavements as it provides anti-slip properties, enhancing slip resistance. To achieve a bush-hammered marble surface, tools made of carbide, an extremely hard material resistant to vibrations generated during processing, are used. For large surfaces to be bush-hammered, a rotary bush-hammering machine is employed, creating various grain sizes on the material: coarse, medium, or fine bush-hammering. On the other hand, in manual processing, bush-hammering is performed using pneumatic hammers from the Cuturi brand, equipped with bush-hammer heads with a hardened steel shank and carbide tips.

Brushing, antiquing

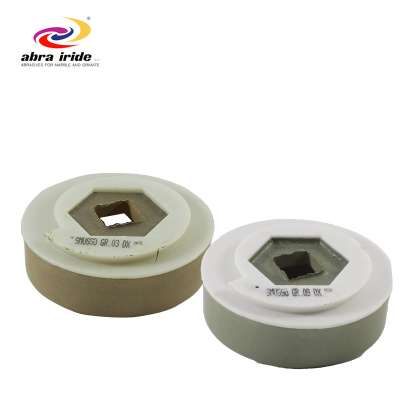

This is a finish that creates a worn, aged appearance to the surface of the marble or stone slab (this is why it is also called antiquing). It is carried out with the use of abrasive silicon carbide or diamond brushes applied to polishing machines or with electric polishing machines. Antiquing brushes are able to dig deeper where the marble is softer, resulting in an irregularly carved surface. The antiqued or brushed finish of marble is increasingly in demand in modern interior design.

Marble and stone carving tools

Stone and marble carving is carried out with the help of compressed air tools or by hand with the Carbide Hand Points, chisels, Hand Jointed teeth chisels, widia bushings for carving, engraving, bush-hammering stone and marble.

Diamond tools

Marble and granite cutting is done with the diamond wheel - for shaping, profiling granite diamond wheels allow us to profile both natural marble and new materials such as quartz, stoneware, bretonstone, laminam, lapitec, synthetic marble.

Articles for marble workers range from diamond discs, diamond wheels, diamond cutters, magnesite abrasives, sintex abrasives, resin and diamond resinoids to silicon carbide cloth.

Manual abrasives

Manual abrasives for finishing marble, stone, glass and wood are used for smoothing, smoothing and polishing both during normal processing and in surface restoration work. The types of abrasives used are silicon carbide, diamond, resin and diamond from which abrasive discs, grinding wheels, cup wheels, flap discs, flap abrasive wheels and diamond flap discs are made. These abrasives are used with the grinder ( Flex, whiskers ), while for manual use for sanding in corners or parts of shaped surfaces, we use abrasive sheets, diamond cloth, diamond abrasive sheets, diamond pads that can be cut into pieces as required and abrasive sponges. Abrasives are divided according to use: dry or wet.

Italiano

Italiano